The wear of the cutting tools is of course an important key for the cut quality. Other criterions have to be taken into account like the supporting heads, the guiding system.

TECHNICARTON's technical team helps you to find the weaknesses of your slotting unit and to find solutions to improve the quality of your machine with specially developped parts.

FeederMore details | |

| Find all the equipment you need for your feeder: - Belts - Suction grits,slides, pads - Rollers - Kickers |

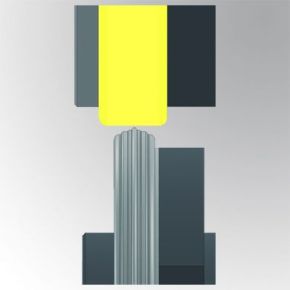

SlotsMore details | |

| We master the whole production of our cutting tools with the best materials, treatments and with the tightest tolerances so that the plays are minimized and you get the best cut quality |

Stitch lap cutMore details | |

| We supply all the components as spares or assembled We can transform your non absorbed systems to a more efficient absorbed system which ameliorated the lap cut but also preserves the life time of the peripherical parts

|

Trim knivesMore details | |

| Trim knives with standard or special thin profile. For an optimized trim cut, choose our spring loaded system for a constent pressure between both upper and lower knives. Available on most of slotting machines. |

ScoringMore details | |

| Special heat treated scoring ring with multilevel profile to minimize the risk 1st sheet rips |

HeadsMore details | |

| Heads |

GuidesMore details | |

|

|

Pull rollsMore details | |

| Pull rolls |